Commercial Wooden Butter Cutter

This Butter Cutter is made of wood, cast iron and steel wire. It would have been used in a Butter Factory to cut large blocks of processed butter into one pound blocks. Its box body is constructed from solid planks of Kauri Pine in the shape of a large, rectangular prism with a steel wire grid at one end and gearing system at the other end. The wooden body is reinforced with 4 iron brackets that latch and brace the solid hinged lid. The machine is supported by a solid stand that brings the workings to bench height.

The open square cutting end of the machine is framed by 4 iron braces which are used to attach the steel wire cutting grid. A guillotine knife is attached by a fixture above the upper side of the box body and would be moved by a wooden handle. Two wooden arms extrude out under this opening to support a tray to collect the 1lb blocks of butter as they exited the machine.

At the other end of the machine an inner, moveable, wooden wall would be pushed towards the grid end by the geared crank system which was powered by an operator turning the crank handle located on the long side at the geared end. As the large butter block was pushed through the machine it would be extruded through the wire grid and the guillotine knife would make cuts along the length of the butter block.

Edward Cherry migrated from Herefordshire England to Australia in 1855 and established a joinery workshop at Gisborne, Victoria. In 1858 he began experimenting with various models of butter churns and by 1875 had enough business to establish a factory. The Cherry works specialised in making all types of butter churns and equipment for both domestic use on farms and small butter factories. During the late nineteenth and early to mid twentieth centuries Cherry & Sons exported products to many countries around the world.

Edward Cherry ran the business with his sons until he died in 1909 and then the business was run by his son George until his death in 1917.

Details

Details

Before it became common to sell 1lb packages of butter, butter was sold to retailers in large blocks. The store owner would then use a length of wire with 2 wooden handles to cut off the amount of butter that was required by the customer and the customer would be charged accordingly. As Butter Factories started competing, they came up with the idea of customised parchment packaging that would promote the Butter Factory and region of origin. This required the factories to determine a standard size and create specialised machinery that would cut and pack large amounts of butter! Consumers quickly adapted to these changes and buying decisions became increasingly influenced by who made the butter and the region which supplied the milk.

The earliest design of a Butter Cutter was a wooden base with thick, rectangular grid incisions that had a wooden lid with a matching grid of steel or iron wire threaded through the outer frame. The block of butter would be placed on the base and as the lid was closed it would slice the butter block into the required pound quantities. Whilst this design was effective it could only handle relatively small blocks of butter.

Whilst this Butter Cutter was not known to be used locally it is highly likely that a similar model was used at this Butter Factory when it opened in 1918.

Other items by Cherry & Sons

More items like this

Other items from Busselton Historical Society

- Galvanised Cream Measuring cups and bucket

- Dazey Jar Churn

- Metal Milk Strainers

- Kangaroo Minute Butter Churn

- Sunrise Butter Churn mounted on wooden milking stool

- Oak Barrel Butter Churn on a stand

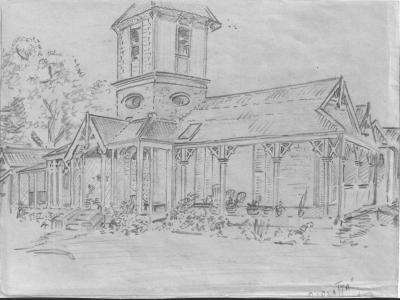

- Sketch - "Villa Carlotta"

- Enterprise #50 Grist Mill

- End over End Barrel Butter Churn

- Galvanised Milk Strainer

- Early Ice Cream Maker

- Early Ice Cream Maker

Scan this QR code to open this page on your phone ->